All job specific ITP’s, check sheets and test sheets will be provided for client approval where required prior to starting any works. Client supplied QA documentation will be utilised where preferred by the client.

The lists below are headers only and do not name each specific test for each piece of equipment. All tests are implied and will be completed as required by the agreed specific tests in the relevant ITPs and specification.

Each site will be tested to the highest standards and will be fully fit for purpose before energisation.

Each site will be tested to the highest standards and will be fully fit for purpose before energisation.

- Point to point testing including drawing highlighting and drawing signing off for record purposes

- Tightness of all terminals and wire pull checks

- Correctness checks of all ferrule markers, labels, installed equipment and equipment ratings.

- Secondary wiring insulation resistance tests

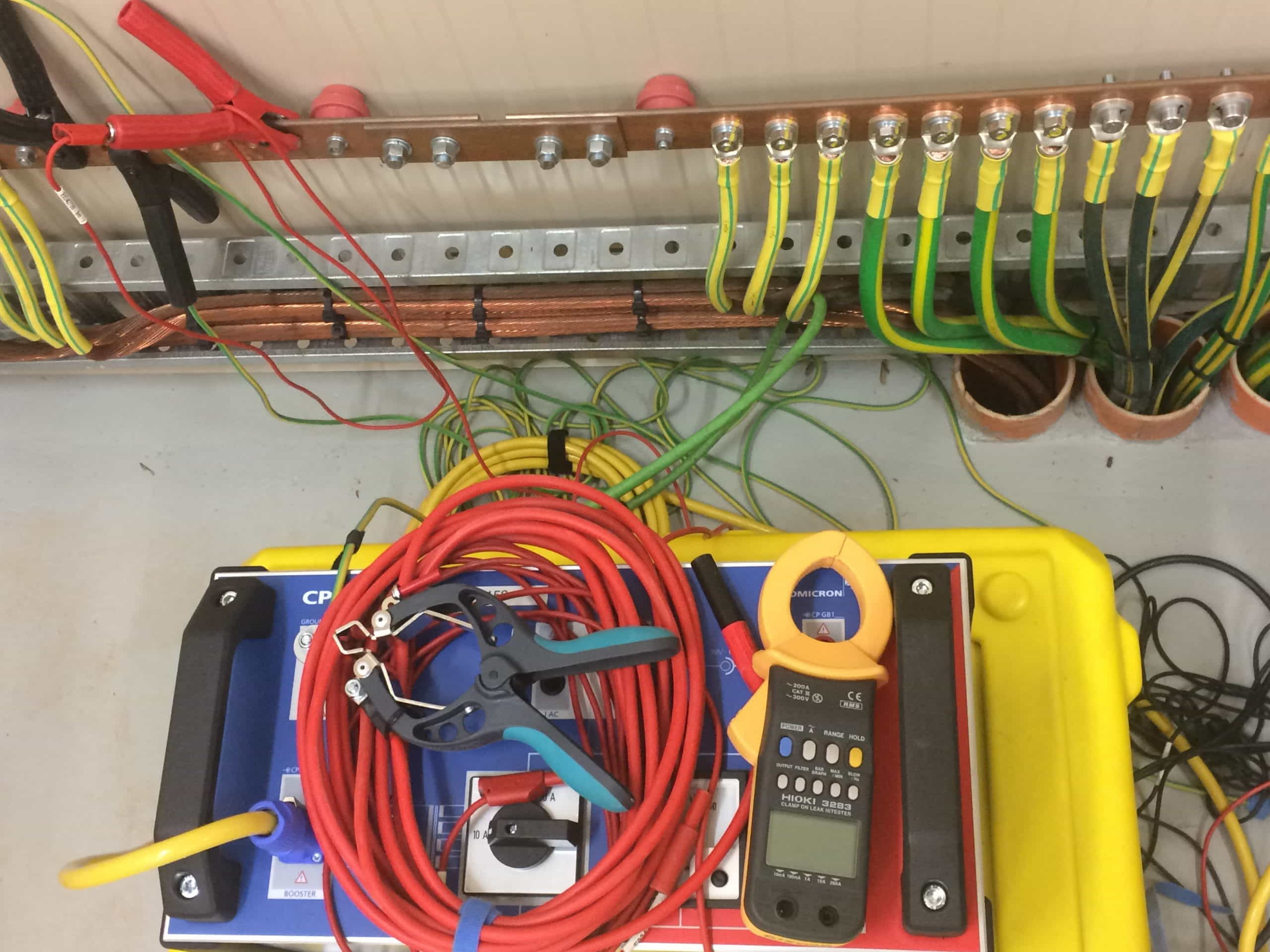

- Secondary earthing including single point earthing checks on CT circuits

- Polarity checks on all AC and DC secondary circuits

Level Two Testing (Site Acceptance Testing of HV, MV and LV primary plant)

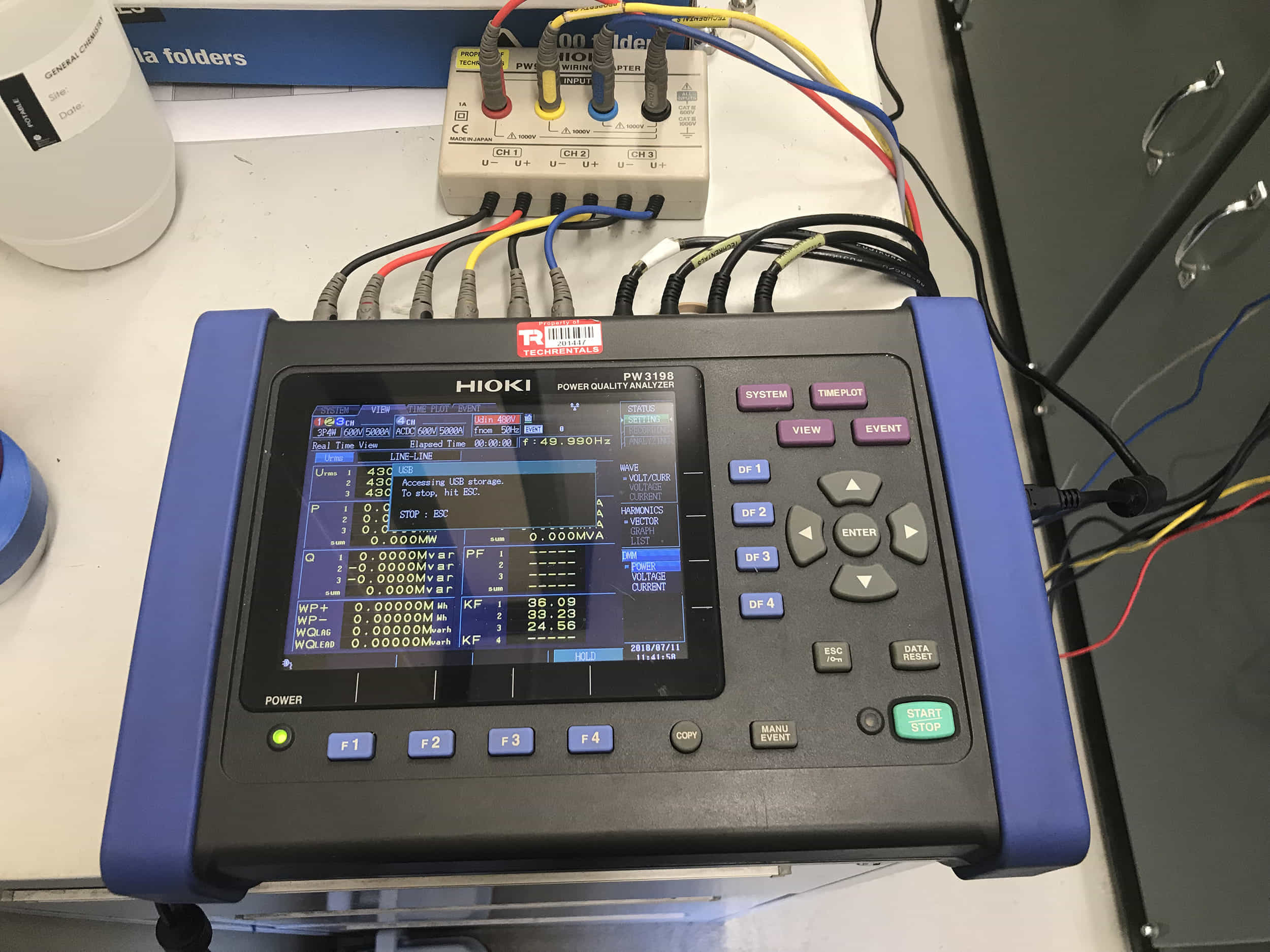

- Current transformer tests including nameplate data collection and comparison with design requirements.

- Voltage transformer tests including nameplate data collection and comparison with design requirements.

- Power transformer tests excluding frequency response analysis

- Single pole and three pole circuit breaker testing

- Capacitor Bank and reactor testing

- Filter Bank testing

- Isolator, earth switch, surge arrestor testing

- Cable testing (higher voltage VLF testing may require specific test equipment)

- Contact and joint resistance tests on cable ends, earth grid risers, busbars and circuit breakers

- Insulation resistance tests

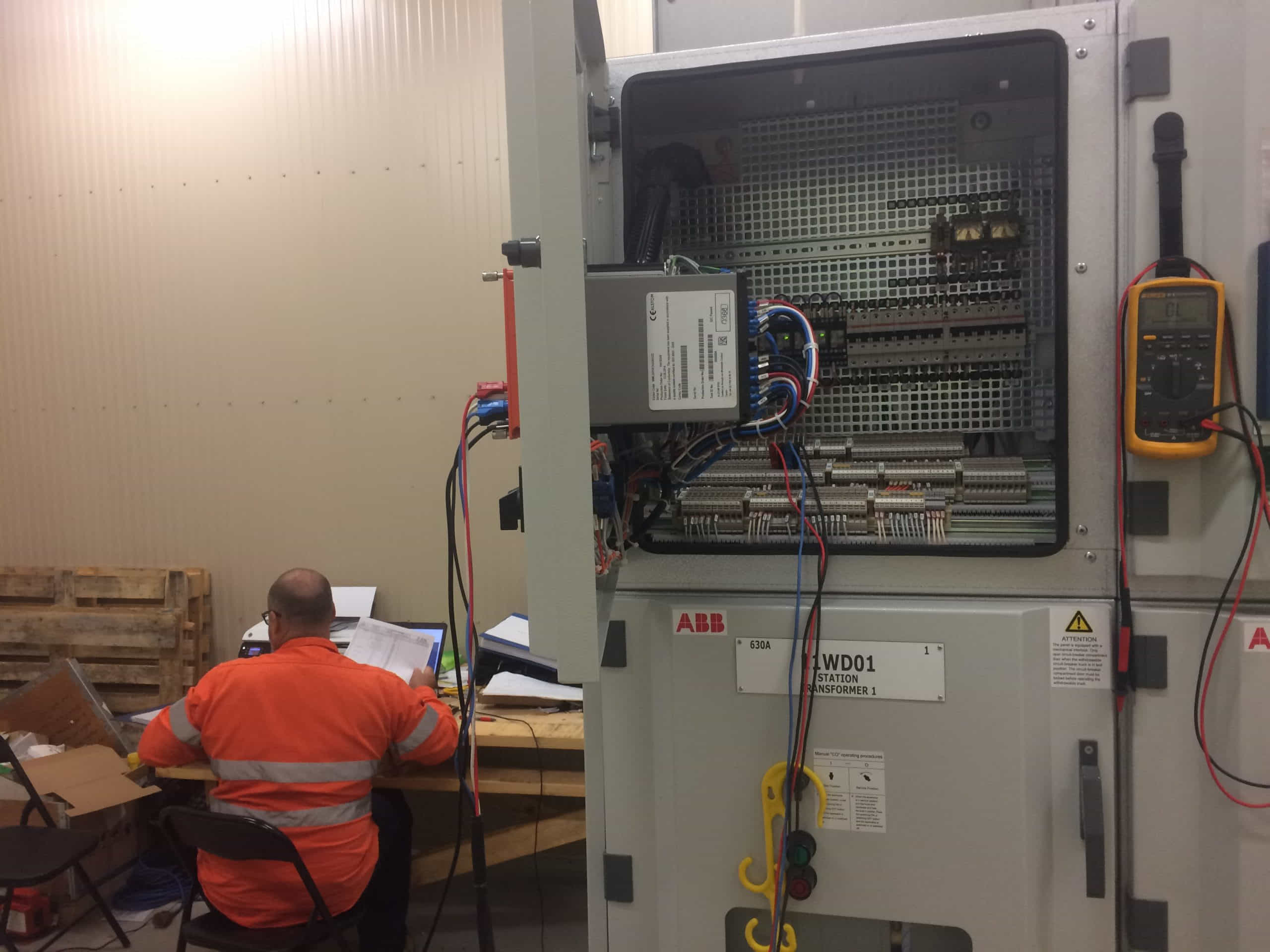

Level Three Testing (Relay logic, analogue inputs, digital I/O, relay characteristics of all applied settings and relay related SCADA testing)

- Non-directional and directional overcurrent, earth fault and sensitive earth fault

- High and low impedance restricted earth fault

- Transformer protection

- Generator protection

- Cable/line differential protection

- Busbar protection schemes

- Distance protection and schemes

- Auto reclose and distance to fault location

- All settings compared to latest settings report

Level Four Testing (Complete integration testing of tested equipment to ensure fit for purpose plant)

- Primary current injection to check relay displays including CT summation checks

- Primary voltage injection to check relay displays and live indicators

- Complete tests to check entire SCADA points list

- Integration of relay binary inputs and outputs

- Compete tripping checks including circuit breaker fail and trip circuit supervision

- Complete closing checks including close circuit supervision

- Heater and fan checks

- Primary operating current checks on busbar protection schemes

- All mechanical and electrical interlocking schemes

- LV automatic changeover systems including the integration of the local standby generator